Should Cost Analysis: Principles and Implementation

In the first part of our three-part guide, we introduce you to the basic principles of should cost analysis and outline the most important steps for the successful implementation of should cost analysis.

Guide "Should Cost Analysis"

Part 1: Principles and Implementation

What is Should Cost Analysis?

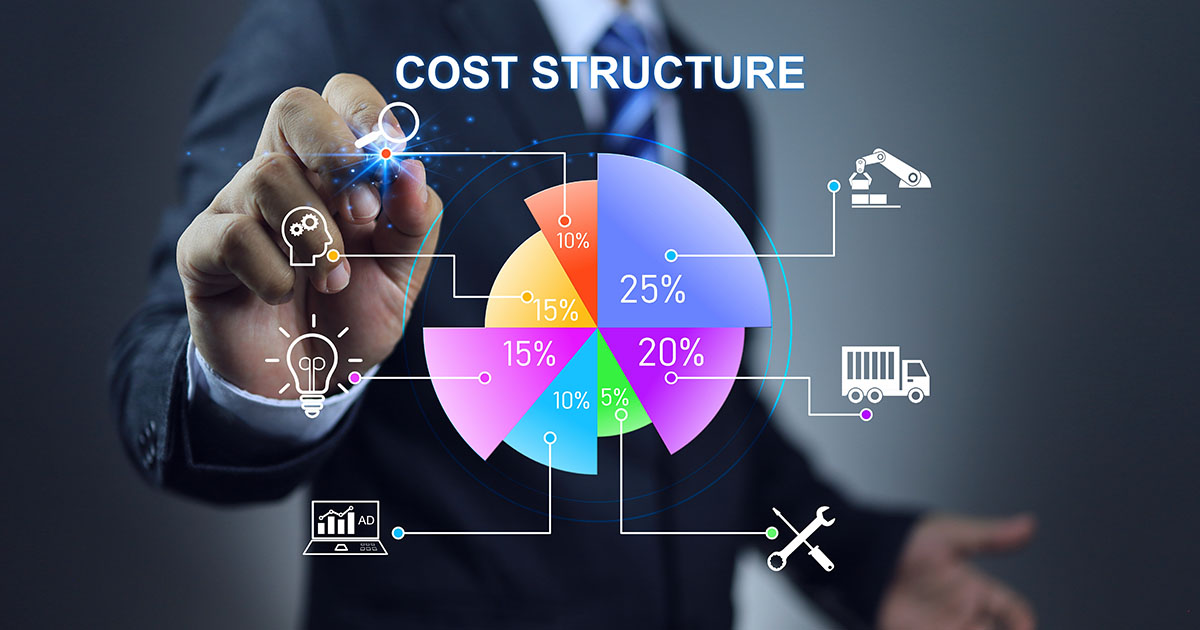

Should cost analysis is a strategic approach to determining the cost of a product or service by analysing its constituent elements and calculating the costs associated with them. This includes the costs of materials, labour, overheads, and profit margin, among other factors. It aims to understand what a product or service should cost under efficient and competitive market conditions, thus providing a benchmark for price negotiations with suppliers and a foundation for strategic sourcing decisions.

Rather than accepting the supplier's quoted price at face value, should cost analysis encourages an understanding of the cost from a fact-based perspective. This approach involves breaking down a product into its fundamental components, understanding the market rates for each, and building up a cost model. This proactive cost management strategy helps businesses to gain a holistic view of a product's cost structure, enabling them to identify opportunities for cost reduction and make more informed purchasing decisions.

In the highly competitive and increasingly complex business landscape, should cost analysis has become a crucial strategic tool. Economic uncertainties, global market fluctuations, and the push for sustainable practices underscore its importance, making it instrumental for businesses striving to optimize their procurement practices and maximize profitability. By offering an in-depth analysis of development and product costs, should cost analysis enables organizations to identify potential savings, drive cost-effective sourcing, and ensure a competitive edge in the market.

Moreover, the growing prevalence of outsourcing and the complexity of global supply chains have made understanding the true cost of products and services more important than ever. Businesses can no longer afford to base their procurement decisions on supplier quotes alone. Should cost analysis provides a more accurate and transparent way to understand development and product costs, empowering companies to navigate their sourcing activities with confidence. It aligns purchasing decisions with market realities and facilitates stronger, fact-based negotiations with suppliers, thus promoting cost savings and enhancing supplier relationships.

The Basics of Should Cost Analysis

Understanding should cost analysis involves grasping the concept of cost modelling, the role of market intelligence, and its link to value engineering.

The Concept of Cost Modelling

At the heart of should cost analysis lies the concept of cost modelling, a process that aims to estimate the costs associated with the production or provision of a product or service. A cost model breaks down a product or service into its component parts and calculates the costs of these individual components based on factors such as raw material prices, labour rates, and overheads.

Cost modelling requires a deep understanding of both the product and its manufacturing process – sometimes even its development process. It involves dissecting the product down to the smallest parts or features, understanding their specifications, and analysing the materials and processes required to produce them. Each component's cost is then calculated by considering the quantity of materials, labour hours, overhead, and other costs involved in its production. The sum of these costs provides a calculation of what the product should cost when developed and produced under efficient and competitive conditions.

By using this approach, cost modelling helps businesses to create a detailed and accurate picture of a product's cost structure, thereby providing them with critical insights for negotiating with suppliers, identifying cost reduction opportunities, and making strategic sourcing decisions.

The Role of Market Intelligence in Should Cost Analysis

Market intelligence plays a crucial role in the should cost analysis process as it supports the cost calculations with real-world data and trends. Market intelligence encompasses a wide array of information, including raw material prices, labour rates, supply chain logistics costs, exchange rates, and even regional energy costs, all of which can significantly impact the cost of production.

In building a cost model, businesses need to gather and analyse relevant market data to ensure that their costings reflect current market conditions. For instance, the cost of a particular raw material used in the production process might fluctuate over time due to changes in demand and supply, geopolitical tensions, or natural disasters. By incorporating up-to-date market intelligence into their should cost models, companies can adjust their cost estimates accordingly and thus avoid costly miscalculations or misinterpretations.

In addition, market intelligence can provide insights into broader market trends that can affect product costs, such as technological advancements, new regulations, and shifts in labour market conditions. By staying informed about these trends, businesses can anticipate future cost changes and make proactive sourcing decisions, further enhancing the effectiveness of their should cost analysis strategy.

The Link between Should Cost Analysis and Value Engineering

Should cost analysis and value engineering are closely interconnected, as both involve a detailed analysis of a product or service's features to optimize costs and maximize value. While should cost analysis focuses on creating a detailed cost model of a product, value engineering seeks to improve the value of that product by optimizing its functionality and cost.

In the context of should cost analysis, the goal is to understand what a product and/or its development should cost given its current design and manufacturing processes. On the other hand, value engineering aims to evaluate whether the current design and manufacturing processes are the most efficient and cost-effective. It involves questioning every element of a product’s design and manufacturing process to see if the same functionality can be achieved at a lower cost without compromising quality.

In essence, while should cost analysis provides a benchmark for what the current product design should cost, value engineering looks for ways to reduce this cost by improving the product's design or manufacturing process. By incorporating value engineering into the should cost analysis process, businesses can not only negotiate better prices with suppliers but also explore opportunities for product redesign and process optimization to further reduce costs and enhance value.

How to Implement Should Cost Analysis?

A should cost analysis process involves steps like identifying product specifications, conducting market research for material and labour rates, building a Should Cost model, and analysing the results.

A should cost analysis can be applied to both manufacturing and development costs. While traditionally its application has been more pronounced in manufacturing where direct costs like material, labour, and overheads are more straightforward to assess, a should cost analysis is equally valuable in the development phase.

Identification of Product Specifications

The first step in the should cost analysis process involves the identification of product specifications. This encompasses a detailed understanding of the product's design, materials, functionality, and performance requirements. Every aspect of the product, from its raw materials and components to the manufacturing and assembly processes required to produce it, must be thoroughly understood, and documented.

Product specifications can include physical attributes such as dimensions, weight, and volume, as well as material properties, manufacturing tolerances, and quality standards. Additionally, it's important to identify and account for any specialized components or processes, such as custom parts, proprietary technologies, or complex assembly requirements.

This detailed understanding of the product is the foundation for building a comprehensive should cost model. By accurately identifying product specifications, businesses can ensure that every element of the product's cost is accounted for in their cost model. This helps in creating a more realistic and accurate should cost calculation, leading to more effective negotiations with suppliers and better-informed sourcing decisions.

Market Research for Material and Labour Rates

Once the product specifications have been accurately identified, the next stage in the should cost analysis process involves conducting thorough market research to determine the current costs of materials and labour rates. This is a crucial step, as these costs are a major component of the overall product cost and can significantly vary over time due to market conditions.

Researching material costs involves identifying the types and quantities of materials used in the product and obtaining up-to-date prices for these materials from reliable market sources. Businesses must be aware of fluctuations in commodity prices, trade tariffs, and the impact of global supply chain disruptions, as these factors can greatly influence the costs of materials.

Similarly, understanding labour rates requires an in-depth study of wages in the regions where the product is manufactured. Labour rates can vary widely across different geographical locations and can be influenced by factors such as local labour laws, wage inflation, and prevailing industry standards.

By incorporating accurate and current material and labour costs into their should cost model, businesses can ensure that their costings are grounded in reality and reflect current market conditions, leading to more accurate and transparent costings.

Building a Should Cost Model

Having identified product specifications and conducted market research for material and labour rates, the next stage in the should cost analysis process is the building of the should cost model. This model is essentially a comprehensive breakdown of all costs associated with the production of a product or service, based on the information gathered in the previous steps.

The should cost model typically includes costs related to raw materials, labour, overheads, and other direct and indirect expenses involved in the manufacturing process. Each element of the product or service is assigned a value (cost or price) based on the market research data, according to the identified specifications.

For instance, the cost of materials is calculated by multiplying the quantity of each material required by its current market price. Labour costs are determined by the estimated time to manufacture each component and the applicable labour rates. Overhead costs, which can include expenses such as utilities, equipment depreciation, and factory maintenance, are also factored in.

The culmination of all these calculations results in a granular, bottom-up calculation of what the product or service should cost under efficient and competitive market conditions. The precision of this model directly affects the accuracy of the should cost analysis, thereby playing a crucial role in strategic sourcing and supplier negotiations.

Analysing and Interpreting the Results

After building the should cost model, the next crucial step is to analyse and interpret the results. This analysis isn't merely about comparing the should cost estimate to the quoted price from the supplier, but it's a comprehensive examination that can provide valuable insights for strategic decision-making.

The difference between the should cost analysis and the supplier’s quote can indicate areas for potential cost savings. For instance, a higher supplier quote might point to inefficiencies in the supplier's manufacturing process, higher-than-average overhead costs, or an inflated profit margin. In such cases, the should cost analysis provides a solid foundation for negotiation with the supplier.

Interpreting the results also involves identifying the cost drivers, i.e., the components or processes that contribute most significantly to the overall cost. Understanding these cost drivers can help businesses pinpoint opportunities for cost reduction, whether by redesigning the product to reduce the use of expensive materials or by finding alternative or more efficient manufacturing processes.

Moreover, the should cost analysis can uncover risks related to cost volatility. If certain materials have highly fluctuating prices or if labour rates are expected to rise, these risks can be mitigated with strategic sourcing decisions.

Overall, the analysis and interpretation of should cost results help businesses to make more informed purchasing decisions, negotiate better terms with suppliers, and identify opportunities for cost savings and process improvements.

In the second part of our three-part guide, we go into detail about the potential benefits that should cost analysis has to offer and outline how should cost analysis is proving to be effective in different industries.

Reliable should cost analysis with 4cost

The software and service solutions from 4cost provide you with a maximum of cost transparency at all phases. For improved cost control and increased profitability.

Request a commitment-free presentation now. Our experts will be happy to advise you on the right solutions for your company.